Electrical Thermographic Inspections

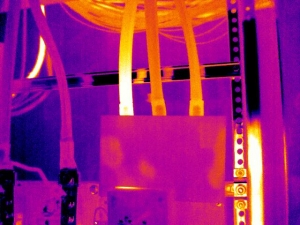

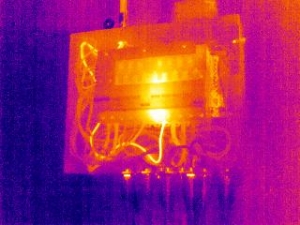

Thermographic inspection of electrical infrastructure using infrared cameras that indicate temperatures. This is known as thermography or radiometric thermal imaging and applied to open switchyards, electrical panels, distribution boards, switches, tap offs, bus bars, and other electrical items. Our inspections utilise Load Correction electrical formula that helps to assess electrical components. These formula offer:

- Load Corrected temperature which estimates temperature based on maximum load

- Fault severity taken from differential between Load Corr and British Standard cable Reference temp set at 75C (65-85C)

- Maximum amps that can be safely run without exceeding the BS Reference temperature set at 75C (65-85C)

Why?

Electricity at Work Regulations Act 1989, Health & Safety at Work Act 1974 and BS 7671 (IEE Wiring Regulations 17th Edition as amended) suggest that electrical infrastructure be regularly maintained and tested to ensure compliance with safety guidelines. Performing a thermographic inspection will highlight problems with electrical infrastructure under load during the testing process as these areas will manifest as anomalous temperatures shown in the live image on the thermal imaging camera.

Incentive to inspect?

By producing a detailed report by a trained professional will help demonstrate that reasonable steps have been taken to ensure you’re electrical infrastructure is of reasonable integrity. Additionally, it may satisfy your insurance company requirements for the fire prevention in electrical systems related scenarios.

Ok so what survey specification do I look for?

The market is unregulated so diligence is required when choosing your inspection company. Points to look for include as a minimum specification:

- Officially trained thermographers at least Level 1 with electrical qualifications

- Camera Resolution: 320×240

- Thermal Sensitivity(NEDT): 100mK or 0.1C

- Reporting Software: Manufacturers freeware is very basic and may limit the quality of reporting and time it takes to deliver. Look for non-freeware. We utilise a purpose built App for the iPad called TICOR which allows us to write the report as we go, trend data between inspections, sync back to an online Web Portal called WEBCOR for instant report retrieval.