Electrical Thermal Imaging Inspections (UK-Wide)

Fast, Compliant & Non-Disruptive Reporting for FM & Compliance Teams

Looking for expert thermal imaging of your electrical systems? TI Thermal Imaging provides Level 2 & Level 3 certified inspections across the UK — trusted by facilities managers, insurers, and data centres for critical compliance and fault prevention.

Why Choose TI Thermal Imaging?

-

Level 2 & 3 ITC Qualified Thermographers

-

Fully insured & experienced in live site access

-

Reports meet compliance with BS7671, BREEAM, and insurance standards

-

Quick-turnaround reports formatted for FM & compliance teams

-

Thermal inspections available out of hours to prevent downtime

What We Inspect:

-

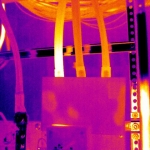

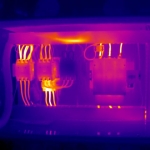

Distribution boards & switchgear

-

Busbars & panel boards

-

Control panels

-

Transformers

-

Server rooms & UPS systems

-

Incoming mains and cable runs

Our Clients Include:

-

Large Facilities Management companies

-

Oil & Gas and energy sector

-

Data centres and hospitals

-

Commercial buildings & retail chains

-

Insurance assessments

Why It Matters:

Prevent fires. Catch overloaded circuits. Stay compliant.

Thermal imaging is a critical part of preventative maintenance — and often a requirement by insurers or for BREEAM credits.

Need an urgent inspection?

We offer rapid-response nationwide. Submit your details and we’ll get back within the hour.

Book an Inspection – sales@thermalimaging.co.uk

Or call now: 020 3089 3222

Our Electrical Inspections involve:

• All panels removed where acceptable, safe to do so and on the Permit to Work

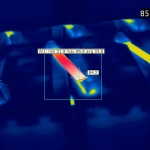

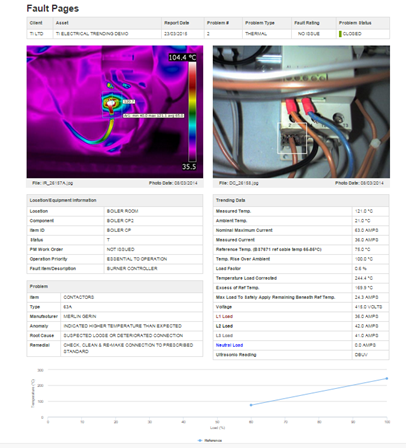

• All electrical equipment/panels/cubicles etc inspected have their own individual trend page which includes a thermogram and digital image, ambient, measured and delta T trending of temperature

• Trending compares data automatically between inspections. Last four thermograms are included on each page and all trend data is captured and displayed in a table and also in graphical format for Measured, Ambient and Delta T (meas/Amb) to allow for condition monitoring of equipment.

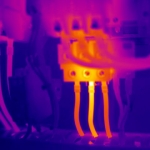

• Detailed fault pages including Load correction formula is utilised during the inspection. Using component rating, actual load, measured temp and ambient temp, the following values are produced:

o Load corr temp: estimate of component temp if operating at 100% load

o Fault severity based on load corr temp – ref temp (from BS7671)

o Estimation of maximum amps to apply whilst keeping temperature beneath reference temp (BS7671)

• Instant report generation which can be emailed to the client at the end of the inspection

• One click upload to WEBCOR for instant client access to inspection data