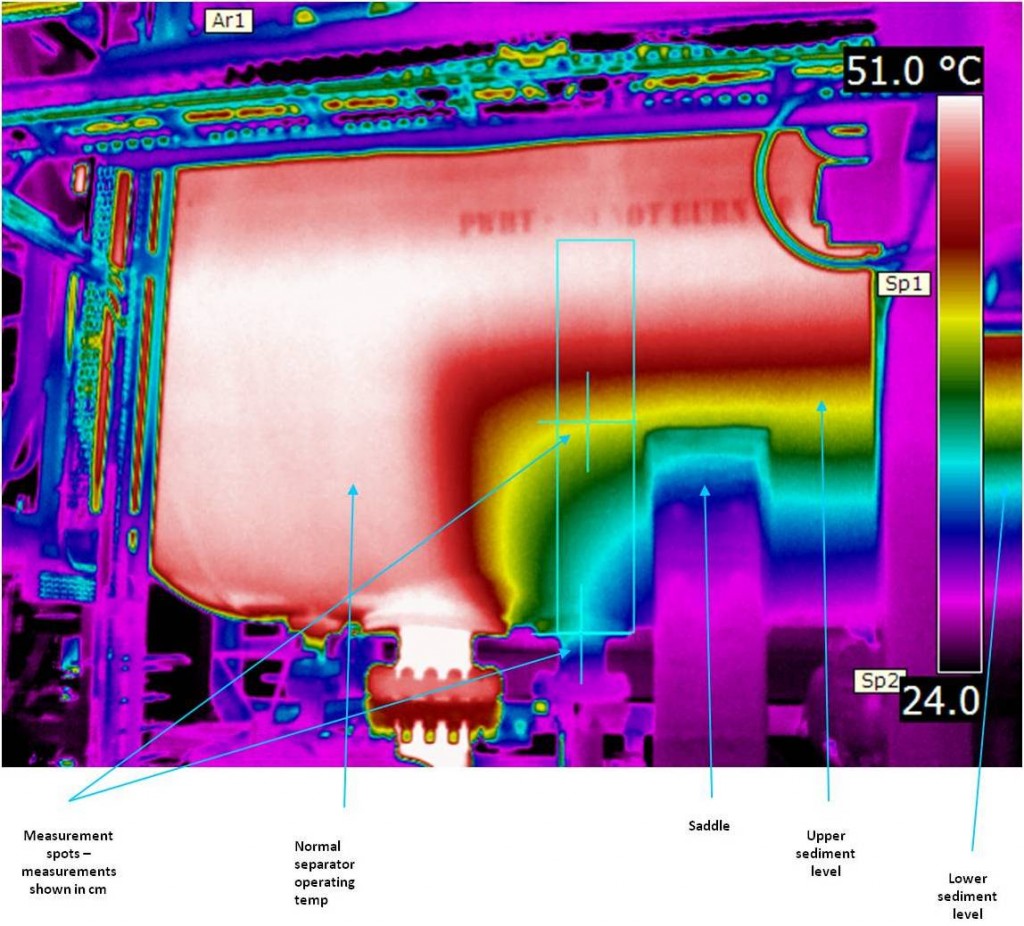

MEASUREMENT – VESSEL INTERNAL LEVELS

The use of thermal imaging cameras on process equipment such as vessels, separators and tanks can span numerous applications from internal fluid or sediment levels to insulation integrity and other structural issues.

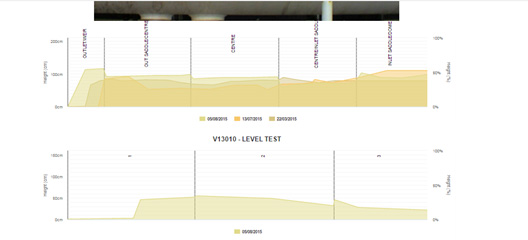

Our purpose-built TICOR™ measurement module can not only indicate where sediment levels lie within a vessel or separator but accurately measure them and offer a cm and % level which is fully trendable between inspections. This will offer you the ability to accurately assess sediment deposits during the initial inspection then to monitor changes during subsequent periodic inspections.

The TICOR™ measurement module is an exceptionally efficient and fast method of providing detailed thermograms of this type of equipment and it provides comparative graphs for each periodic inspection.